What sets Schröder apart within the industry?

We work under a philosophy we refer to as the “5M Model.” Each of the “M” elements represents part of a comprehensive overview. Since we control every aspect of design and production, and thanks to the available resources, we’re able to easily convert a client’s needs and requirements into actual products that surpass their expectations.

5Ms MODEL

1ST M - MANPOWER

To develop footprint solutions for different clients, we work as a team, with Passion and Care!

Here, at Schröder, key positions have received intensive trainings from Japanese or European experts, who have years of hand-on experience in the stainless steel fabrication industry.

That’s why our team can develop various solutions for our client, based on their specific requirements, whether it’s a hotel/resort, restaurant QSRs, cloud kitchen or a home kitchen.

2ND M - MACHINERY

Thanks to CNC latest technology from Germany and Japan, we can turn raw stainless steel materials into delicate or sophisticated products.

Trumpf– Fiber Laser Cutting Machine

- Highly-accurate and speedy cuts for any shapes and thickness up to 8mm.

- Can handle jobs at any complexity.

- Ensure no damage to surface of materials of all kinds, whether black, copper, or bronze stainless steel.

V-Cutting Machine

- V-cut machine ensure an outstanding look for FOH products.

- Minimize the gap(s) between products eliminate bacteria growth and improve food safety.

- For illustration, if there is a gap between the Oven and Counter, bacteria can grow or insects can even hide there.

Trumpf - Bending Machine

- A bending machine serves for the purpose of assembling a bend on a work piece.

- CNC bending machine with proper sets of tools can work with different types of material, thickness, finish and profile.

- With modern bending machine, we can handle very complicated profile with consistency, and precision and at high productivity.

Laser Welding Machine integrated with Robot

- With laser welding machine, the products are even more perfect with slim welding seams that need much less polishing.

- Furthermore, the productivity is 3-6 times higher than manual welding.

- We are studying some products for mass production to integrate our laser welding machine to Robot in order to increase productivity and product quality consistency.

3RD M - MATERIAL

Imported from USA, Japan, Taiwan, Korea, raw materials and components & parts have been selected carefully to fabricate the best possible quality products.

STAINLESS STEEL

For stainless steel sheets and coils, for a smooth and flawless surface, we are using POSCO, ranked third biggest worldwide producer of raw steel in 2010 or ThyssenKrupp AG - a German multinational conglomerate, ranked tenth-largest worldwide by revenue in 2015.

COMPONENTS & PARTS

At Schröder, components and parts are imported from Component Hardware (USA), T&S (USA, China), Sugigo (Japan), Compex (Italy), Ethos (Germany/Korea).

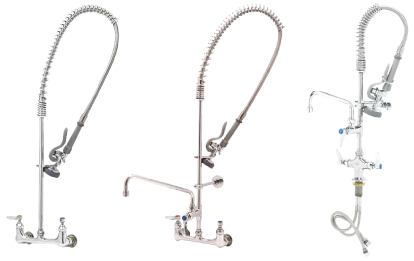

T&S Brass- Faucet (USA/PRC)

Pre-rinse - Faucet (Optional)

Sugico Waste Drain (Japan)

Compex guide rail (Italy)

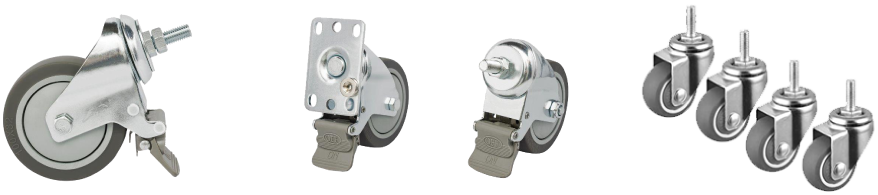

We are using many kinds of castors, depending functionality and load of the products, typically Ethos from Germany, or Korea.

4TH M - METHOD

WITH STRONG R&D CAPABILITY, WE CAN TURN SKETCHES INTO REALITY

With our expertized manpower and their infinitive creation, we can develop numerous solutions for our esteem client.

A yatch-shaped cooking suite for All Day Dining Restaurant made by Schröder, integrated with custom made refrigerators, magnificently supported by LED light from Schröder’s exhaust hood.

GRILL STATION BLOCK

A combination between Grill station, under-counter chiller and stainless steel cabinet, ideal for pool parties, not only at hotels or resorts but also at big villa houses or penthouses with a swimming pool.

CURVED BAR

Equipped with modern machinery, good workmanship and technical know-how, Schröder can easily customize products, for Front – Of – House (FOH) areas, following the curve profile of the bar/show kitchen, whether Oval shape or round shape. Even the door can be bended in curve shape to create a better look and hygiene by minimizing the gaps between equipment. In this way, designer can freely unleash their creativity in designing the bars or FOH kitchens.

5TH M - MANAGEMENT

Schröder operates according to international standards, and ISO is one of the criteria aiming to bring the highest quality products and services to partners and customers in the world.

Environmental Management

We at SCHRÖDER are a dedicated group of individuals driven to manufacture and sell high-quality sheet metal components in compliance with customer specifications by enhancing the efficacy of the Quality Management System through continuous process improvement.

- Product quality complies with ISO 9001:2015

- Items with a 1/1000th of a millimeter precision.

- From the technical drawing to the finished product, product satisfaction is evaluated in precision, accuracy and consistency.

- The company’s large-scale production expertise with high-quality fabrication has been validated by the projects with hotel operators, QSRs, and key dealers.

Quality Management

Pursuing sustainable development, we at SCHRÖDER are dedicated to providing a better world for our children by producing people- and environment-friendly products.

Our factory has been designed to be environmentally friendly with green trees and flowers surrounding the office and workshops. We also invested in all available facilities and equipment to minimize air, water, or noise pollution. We gather waste and recycle it into raw materials so that it can be reused.

Occupational & Health Management

For workplace health and safety management, we have ISO:45001 certification.

To build a safe and accident-free environment for employees in the plant and on project sites, the internal proprietary safety program that we have been rigorously following and reinforcing on a yearly basis are as follows:

- Educated employees that accidents are caused rather than just happen, and that they can be avoided

- Trained employees on safe working techniques

- Enforcing all safe working practices doggedly

- Ensuring that all workers wear protective equipment such as hard hats, safety belts, gloves, goggles, masks, face shields, ear muffles, safety, and so on

- Guaranteeing that the equipment supplied to them meets suitable standards

- Utilizing standard scaffolding and ladders when working at heights.